Research, Development, & Testing

Whatever challenge you’ve got.

Whether your challenge is weight, cost, corrosion, schedule, environmental factors, or stopping power, we’re uniquely equipped to design, build, and qualify armor solutions optimized to your needs—and quickly. Because human lives are at stake. And performance, budget, and schedule matter.

Material Capabilities.

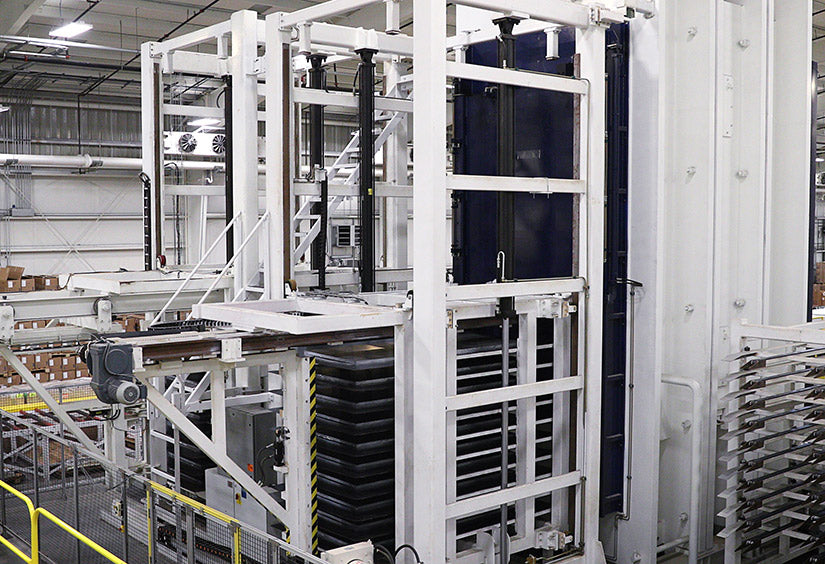

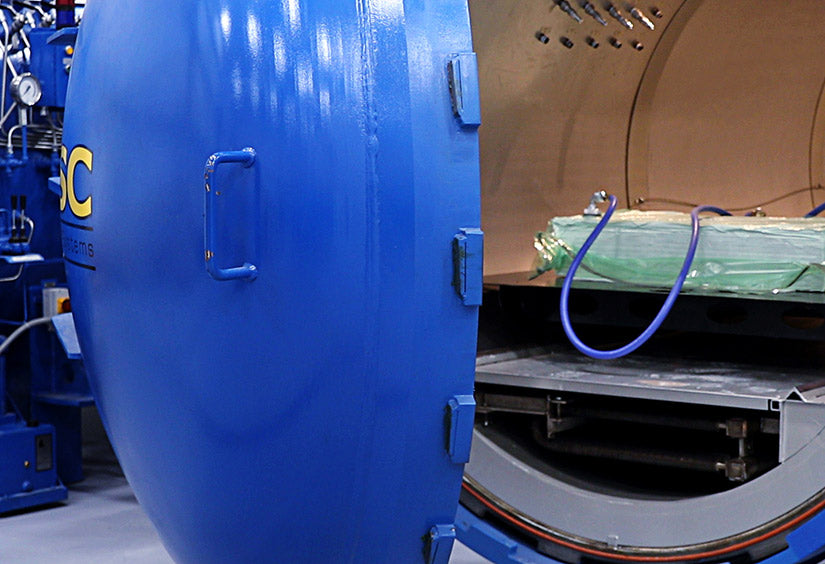

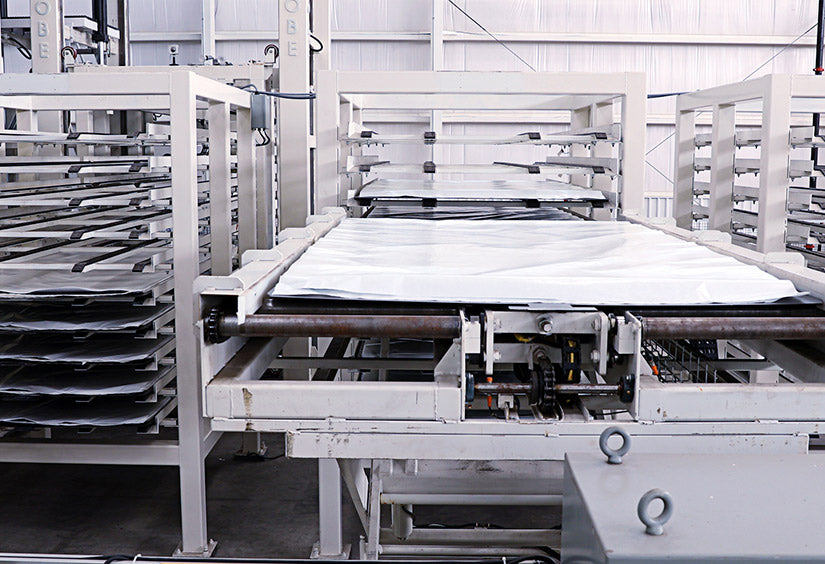

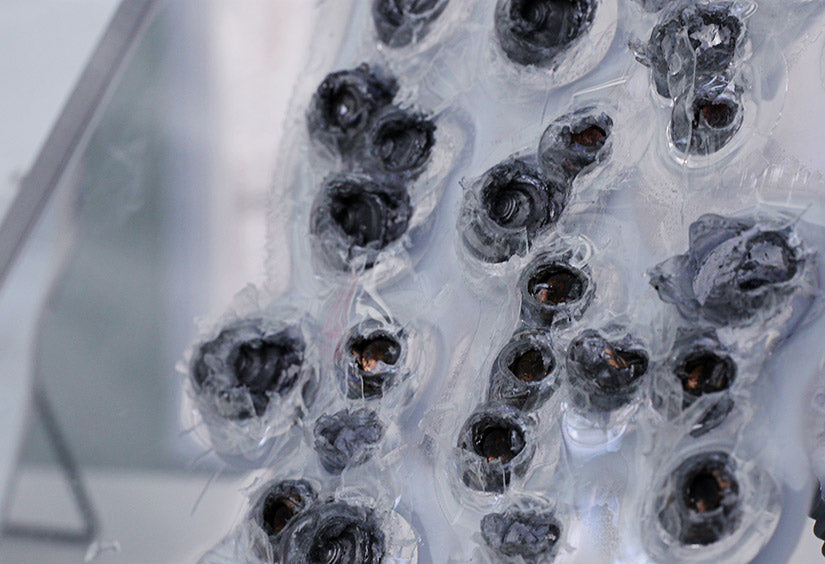

Composite lamination at large scale and volume

Includes polyethylene prepregs, aramids, and many other materials.

Tempered aluminum

Processing of aluminum materials to deliver ballistic performance.

Formed metals

Shaping high hard steels and other metals in complex geometry with ballistic performance via HWSSQTM metalworking services.

Armor kits for land, air, and sea platforms

Ballistic performance designed for seamless integration into military, law enforcement, and commercial platforms.

Integrated kit design and engineering

Selection of material solutions based on environmental and operational factors.

Body armor

The lightest body armor designed to protect against specified threats with limited deformation.

Experienced with government & commercial programs, ranging from rapid prototyping to full-scale production.

- FFP

- Cost-Plus

- DCAA approved accounting system

Reinforcing our nation’s infrastructure.

Since 2002, no other company has done as much as Hardwire to protect bridges and fortify critical infrastructure around the United States.